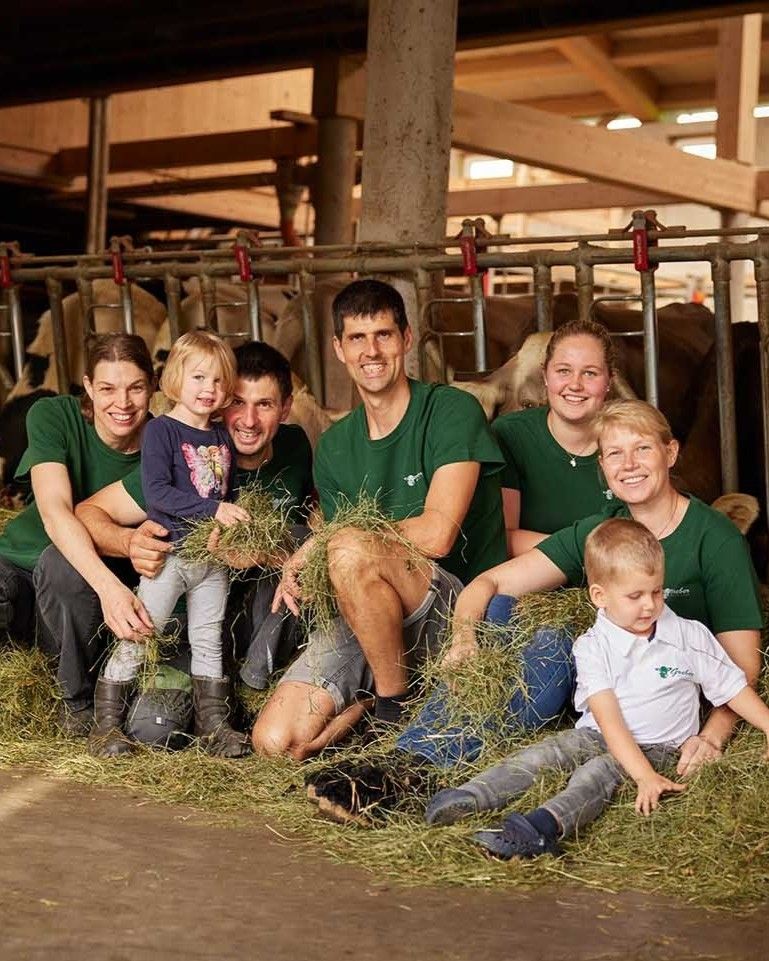

A dairy farm located in the Austrian Alpine region required a stable and scalable energy infrastructure to support continuous agricultural operations. The farm experienced recurrent voltage fluctuations, limited grid headroom, and increasing electrical demand driven by modernization of livestock and milk-processing equipment. To address these constraints, the engineering contractor designed a high-reliability hybrid energy system built around Pytes V5 low-voltage (51.2V) LiFePO₄ battery modules and Victron inverter-charger technology.

The deployed solution delivers approximately 500 kWh of usable storage, integrated with a large PV array and a multi-layered power control architecture. This system now ensures stable operation across agricultural loads, residential buildings on site, and refrigeration systems essential for dairy processing.

Project Background: Growing Energy Demands in Agricultural Operations

The dairy farm’s daily activity relies on a range of electrical equipment that must operate without interruption, including:Milking machines; Milk cooling and refrigeration systems; Automated feeding and livestock-care equipment; Ventilation and lighting; Food processing and storage; Residential housing and essential services.

Even a brief outage can compromise milk quality, interrupt livestock routines, or stall time-sensitive equipment, potentially resulting in significant economic loss. Additionally, seasonal weather patterns in Alpine regions can cause inconsistent solar availability, while local grid limitations restrict the farm’s ability to install higher-capacity PV systems.

The owners needed a long-term solution that would:

1. Stabilize power supply for all agricultural processes

2. Increase self-consumption of solar energy

3. Reduce reliance on the grid and conventional generators

4. Enable future capacity expansion without infrastructure barriers

The combination of high-capacity PV and Pytes V5 storage offered the flexibility and reliability required for this type of diversified farm environment.

System Overview: A Large-Scale, Modular Energy Storage Architecture

To meet the farm’s operational requirements, the engineering team designed a storage-centric system built around the Pytes V5 low-voltage battery. The final system includes:

1. Solar Generation

A large PV array installed across available roof surfaces, sized to support daily load profiles while generating excess energy for storage.

2. Energy Storage

● 100 Pytes V5 lithium battery modules

● Approx. 500 kWh of total installed capacity

● Organized into multiple racks to maximize serviceability, thermal stability, and redundancy

● Designed for multi-day autonomy during low-sunlight periods

3. Power Conversion and Control

● Victron inverter-chargers for power management and load control

● MPPT charge controllers for optimal PV harvesting

● A central monitoring platform enabling real-time performance tracking and remote diagnostics

The integration of Pytes V5 modular LV energy storage with Victron inverter-charger systems has transformed the Alpine dairy farm’s energy infrastructure into a stable, autonomous, and cost-efficient platform. The solution provides long-duration backup, reliable power quality for motor-heavy agricultural loads, and measurable economic benefits—most notably €30,000 per year in reduced energy expenses, delivering a short payback period.

This deployment demonstrates a robust engineering model for agricultural facilities seeking large-capacity solar-plus-storage solutions that combine predictable performance, scalability, and operational reliability.

For agricultural operators facing similar challenges—grid instability, expanding power needs, and pressure to reduce operational costs—Pytes provides a proven, scalable pathway to long-term energy resilience.

Pytes continues to support farms, rural facilities, and commercial users worldwide with dependable energy storage solutions engineered for safety, performance, and real-world reliability.